De-OX: An Innovative Way to Reduce Arena Costs

In a recent case study by Enbridge Gas Distribution, the De-OX Ice Making System single-handedly reduced a facility’s greatest arena expenses: hydro and natural gas costs.

The study shows a facility utilizing the De-OX could see a “natural gas bill cut in half”.

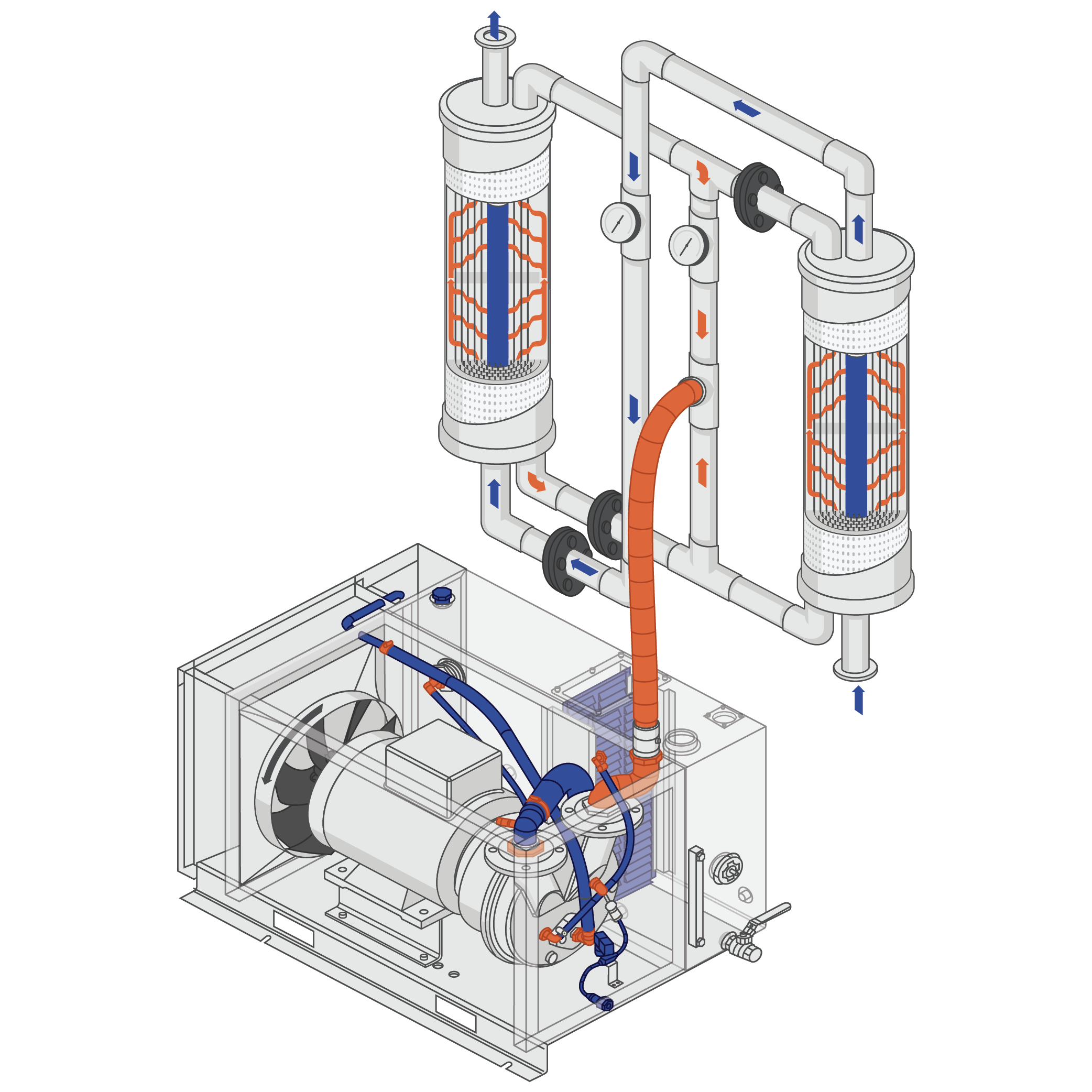

An innovative technology, the De-OX is a complete water treatment system that removes dissolved oxygen from the water before building or resurfacing the ice, leading to ice that freezes faster. This system is proven to be economical (by lowering energy consumption and reducing refrigeration costs), ecological, and eliminates the need to add chemicals.

The study goes on to say, “electricity use is down as well because the ice surface can be kept at a higher temperature, reducing compressor runs. The energy savings make for a substantially reduced carbon footprint. And cold water resurfacing has enhanced playing conditions. The ice freezes quicker and harder, the surface stays dry, and lines are crisp and bright.”

De-OX Case Study Results:

- Estimated 15,235 m3 annual natural gas savings

- 19% reduction in normalized gas load

- CO2 (greenhouse gas) reduced by over 29,000 metric tonnes

- Electricity savings from reduced compressor runs

- $18,973.63 Enbridge Energy Leaders incentive

“Using cold water for ice resurfacing also reduces costly electricity demand spikes. Overall energy cost savings of several thousand a year make for an attractive project payback.”

Additionally, facilities with the De-OX Ice Making System may be eligible to receive rebates from various gas and hydro utilities across North America.

Contact Steve Dawe for info.